Soil degradation, nutrient depletion, and declining agricultural productivity are persistent challenges in modern farming systems. Biochar has emerged as a scientifically validated soil amendment capable of addressing these issues through long-term carbon stabilization and soil structure enhancement. Advanced biochar production equipment enables controlled conversion of biomass into high-quality biochar with consistent physicochemical properties. Among various feedstocks, coconut shells are particularly valued due to their high lignin content and fixed carbon yield, making coconut shell charcoal machinery a critical component in scalable biochar production for agricultural applications.

Biochar as a Functional Soil Amendment

Biochar is characterized by a highly porous matrix, extensive internal surface area, and strong cation exchange capacity. These attributes enhance soil aeration, improve water retention, and facilitate nutrient adsorption. When incorporated into agricultural soils, biochar reduces nutrient leaching and increases fertilizer use efficiency. The stability of biochar carbon also allows it to persist in soil for decades, contributing to long-term soil fertility improvement rather than short-lived nutrient supplementation.

Role of Controlled Pyrolysis Technology

The agronomic performance of biochar is directly influenced by production conditions. Coconut shell charcoal machinery employs controlled pyrolysis under oxygen-limited environments, allowing precise regulation of temperature, heating rate, and residence time. These parameters determine pore structure development, pH level, and surface functional groups of the resulting biochar. Uniform thermal processing ensures repeatable quality, which is essential for large-scale agricultural deployment and scientific validation of soil health outcomes.

Enhancing Soil Microbial Activity

Healthy soil ecosystems depend on active microbial populations. Biochar produced using coconut shell charcoal machinery provides a favorable habitat for beneficial microorganisms due to its porous architecture and surface complexity. Microbial colonization within biochar pores improves nutrient cycling and organic matter decomposition. This symbiotic interaction enhances soil biological activity without introducing chemical residues, supporting regenerative agriculture practices and long-term soil resilience.

Carbon Sequestration and Climate Co-Benefits

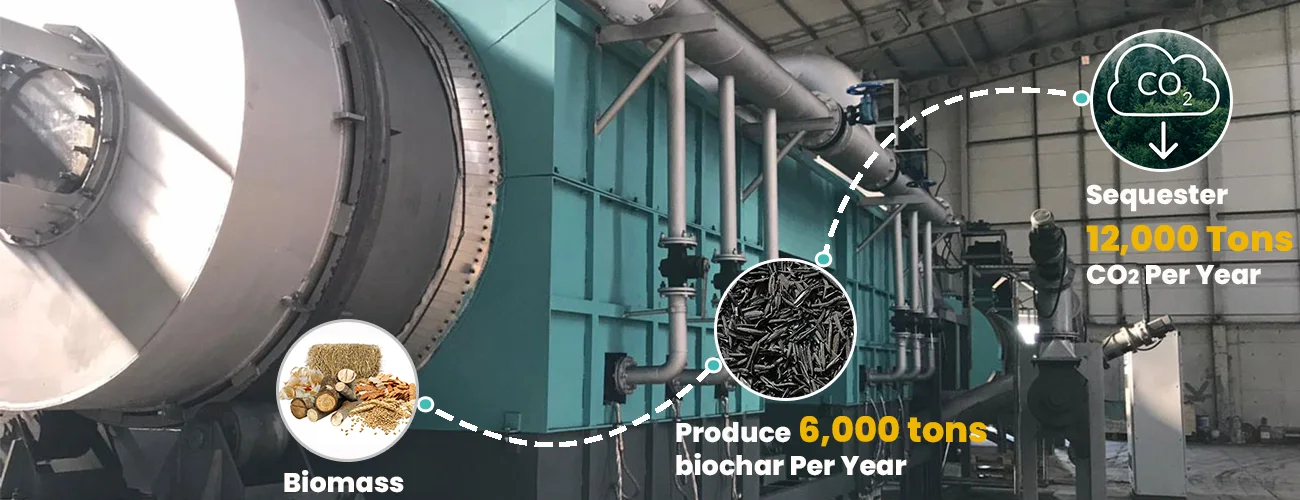

Beyond agronomic benefits, biochar production offers measurable climate advantages. Coconut shells, often treated as agricultural waste, are converted into stable carbon forms rather than decomposing and releasing carbon dioxide. Coconut shell charcoal machinery facilitates this transformation efficiently, locking carbon into a recalcitrant structure suitable for soil application. This process aligns with carbon sequestration strategies and supports climate-smart agriculture by reducing net greenhouse gas emissions from biomass waste streams.

Operational Scalability and Resource Efficiency

Modern coconut shell charcoal machinery is designed for continuous or semi-continuous operation, enabling scalable biochar production with predictable output. Energy recovery systems often utilize pyrolysis gas to sustain reactor temperatures, reducing external fuel demand. This closed-loop operational design enhances resource efficiency while lowering production costs. As a result, biochar becomes a viable input not only for specialized crops but also for broad-acre agriculture.

Long-Term Soil Performance

The cumulative impact of biochar application extends beyond immediate yield improvements. Over time, soils amended with high-quality biochar exhibit improved aggregate stability, reduced compaction, and enhanced resistance to erosion. Coconut shell charcoal machinery supports the consistent production of biochar suited for long-term soil conditioning rather than short-term intervention.

Incorporating biochar produced from coconut shells into agricultural systems represents a technically sound and environmentally robust strategy for improving soil health. With reliable production equipment and controlled processing conditions, biochar becomes a durable asset for sustainable land management and agricultural productivity enhancement.