The concept of a circular economy emphasizes the transformation of waste streams into valuable resources, minimizing environmental impact while maximizing economic efficiency. Charcoal making machines, particularly when combined with a continuous carbonization furnace, offer a practical avenue for implementing these strategies in both agricultural and industrial contexts. By converting biomass residues into energy and high-value carbon products, these systems exemplify the potential of technology to close resource loops and promote sustainable production models.

Maximizing Resource Utilization

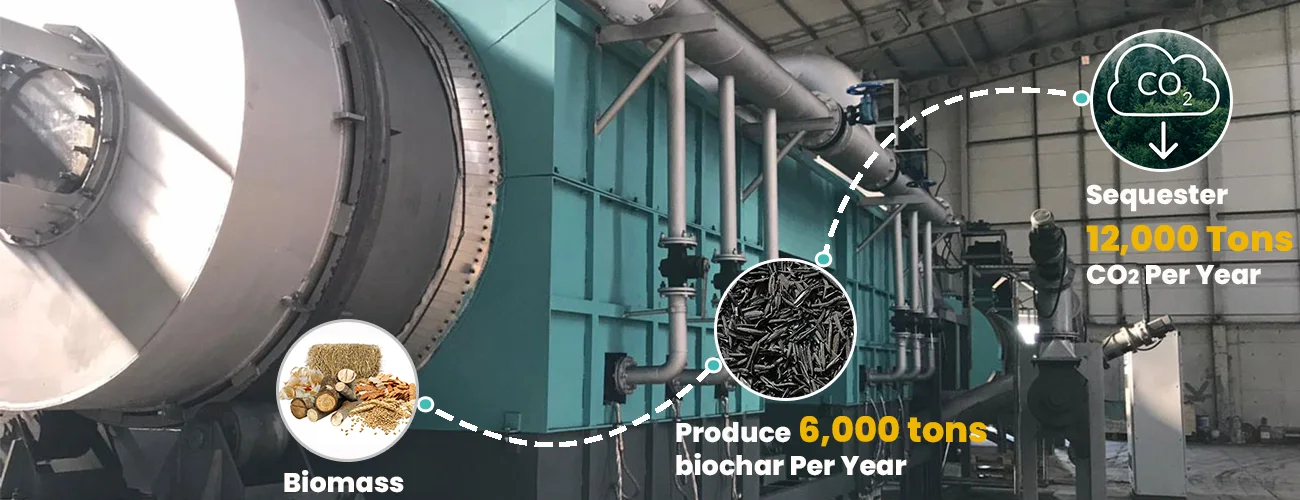

Integrating a charcoal making machine with a continuous carbonization furnace enables the full exploitation of biomass feedstocks. Agricultural residues, forestry byproducts, and organic industrial waste can be carbonized efficiently, yielding high-calorific charcoal while reducing raw material waste. The continuous carbonization furnace allows for uninterrupted processing, improving throughput and maintaining consistent product quality. This maximization of resource utilization not only supports circular economy principles but also enhances the economic viability of biomass processing operations.

Environmental Impact Mitigation

Charcoal making machines contribute to environmental sustainability by preventing the open-air burning of biomass, a common source of air pollution and greenhouse gas emissions. The continuous carbonization furnace ensures precise thermal control, minimizing the release of volatile organic compounds and particulate matter. Additionally, the process captures residual gases and condensates, which can be recycled for energy recovery or converted into supplementary products. This closed-loop system aligns with circular economy objectives by reducing environmental burdens while generating usable energy and carbon-rich byproducts.

Integration with Renewable Energy and Industrial Applications

Charcoal produced from biomass residues can serve as a renewable fuel for industrial heating, power generation, or residential energy needs. When paired with a continuous carbonization furnace, the system ensures high energy density and uniform quality, suitable for a variety of applications. Beyond fuel, biochar generated during the process can enhance soil fertility, improve water retention, and sequester carbon, providing both ecological and agronomic benefits. Such multifunctional outputs exemplify how circular economy frameworks convert waste into multiple streams of value.

Economic Advantages and Operational Efficiency

The adoption of charcoal making machines integrated with continuous carbonization furnaces offers substantial economic benefits. Reduced waste disposal costs, improved energy recovery, and the production of marketable charcoal or biochar create diversified revenue streams. Continuous operation reduces labor intensity and downtime, while consistent product quality supports market competitiveness. For agricultural cooperatives or industrial parks, this combination presents a scalable solution that aligns profitability with sustainability goals.

Future Directions in Circular Biomass Processing

Emerging innovations in charcoal technology are expanding the potential of circular economy strategies. Automation, enhanced thermal efficiency, and real-time monitoring allow for more precise control of carbonization processes. Integration with other waste-to-energy technologies, such as pyrolysis or gasification units, can further diversify outputs and improve resource efficiency. As circular economy principles become central to policy and business strategies, charcoal making machines equipped with continuous carbonization furnaces are poised to play a pivotal role in sustainable biomass utilization.

By converting biomass residues into energy, carbon products, and soil amendments, charcoal making machines integrated with continuous carbonization furnaces demonstrate a pragmatic approach to circular economy implementation. They exemplify how technological innovation can transform waste streams into valuable resources, fostering environmental sustainability, operational efficiency, and economic resilience.

No comments:

Post a Comment